- +917683945499

- info@shree-engg.com

Automatic

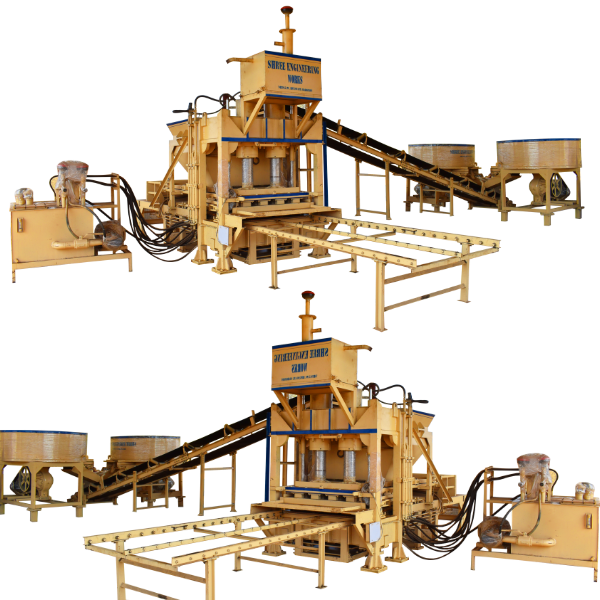

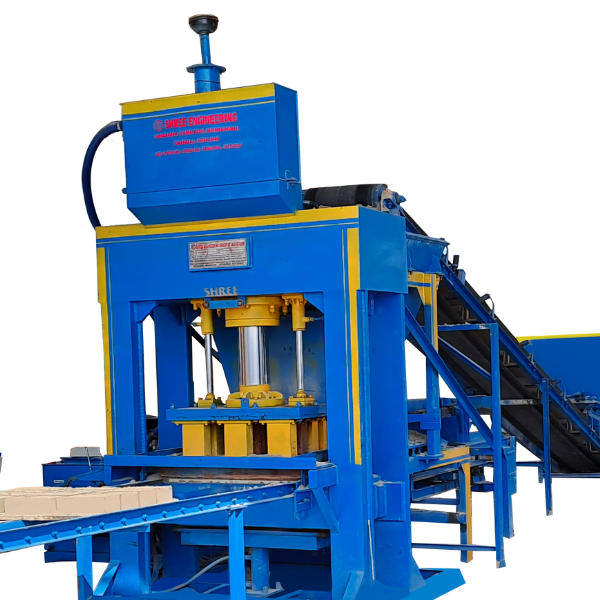

20 Bricks Automatic Fly Ash Bricks Machine

The 20 Bricks Automatic Fly Ash Bricks Machine is a state-of-the-art manufacturing unit designed to enhance the efficiency and productivity of brick production in the construction industry. Here are some key features and benefits:

High Production Capacity: Capable of producing 20 bricks per cycle, this machine significantly boosts output, making it ideal for large-scale manufacturing needs.

Full Automation: The fully automated system minimizes human intervention, ensuring consistent quality and reducing labor costs. Automation also streamlines the production process, enhancing overall efficiency.

Environmental Benefits: Utilizes fly ash, a byproduct of coal combustion, promoting recycling and reducing waste. This makes the machine an eco-friendly option in the construction industry.

- BRICKS PER STROKE :

- TECHNOLOGY :

- Pressure :

- Model Available :

- Pan Mixer Capacity :

- Application :

- Total Power :

- 20

- Hydraulic Press

- 3000 PSI

- Normal, Belt Ejection , High Speed

- 1500 - 2000 KG

- Fly Ash Bricks

- 48 HP

- Per Shift production

- Operation :

- Tonnage :

- Conveyer Lenght :

- Oil Cooler :

- Warranty :

- 24000

- Automatic

- 220MT

- 20 Feet

- Yes

- 1 Year

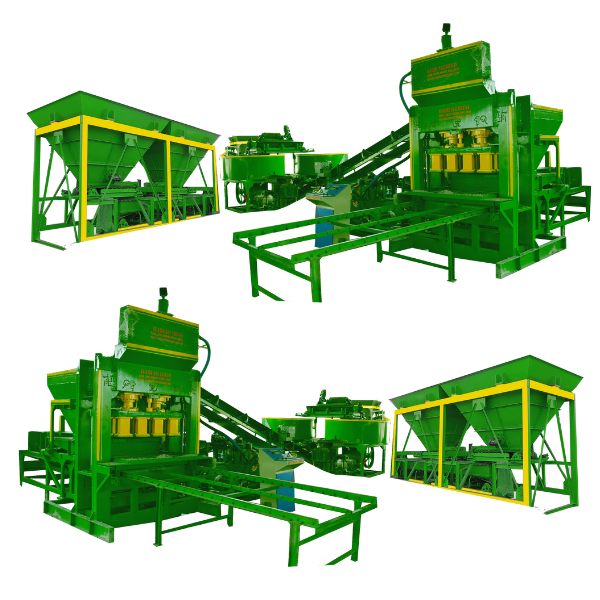

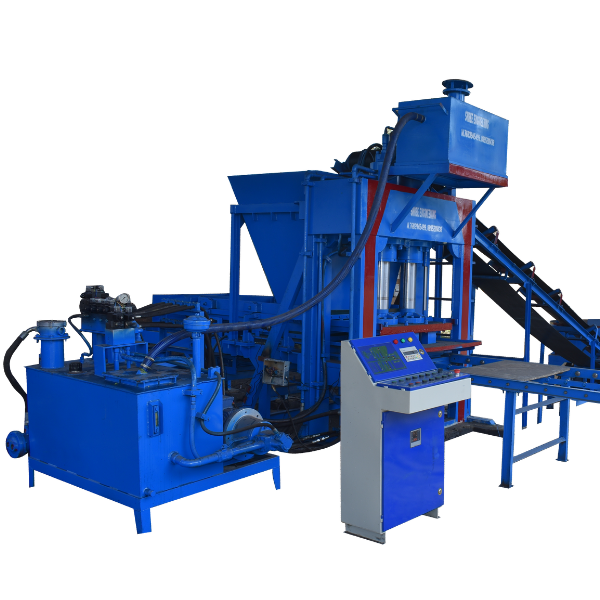

16 Bricks Automatic Fly Ash Bricks Machine

The 16 Bricks Automatic Fly Ash Bricks Machine is a state-of-the-art industrial device designed to streamline the production of fly ash bricks. Here are some key features and benefits of this machine:

High Production Efficiency: This machine can produce up to 16 bricks per cycle, making it highly efficient for large-scale production needs.

Automation: The fully automatic system ensures minimal human intervention, reducing labor costs and increasing productivity.

Use of Fly Ash: By utilizing fly ash, a byproduct of coal combustion, this machine helps in recycling waste material, contributing to environmental sustainability.

Consistent Quality: The machine ensures uniform size and shape of bricks, which is crucial for maintaining the quality and structural integrity of construction projects.

- BRICKS PER STROKE :

- TECHNOLOGY :

- Pressure :

- Model Available :

- Pan Mixer Capacity :

- Application :

- Total Power :

- 16

- Hydraulic Press

- 3000 PSI

- Normal, Belt Ejection , High Speed

- 1000-1500 KG

- Fly Ash Bricks

- 37 HP

- Per Shift production

- Operation :

- Tonnage :

- Conveyer Lenght :

- Oil Cooler :

- Warranty :

- 21000

- Automatic

- 220MT

- 20 Feet

- Yes

- 1 Year

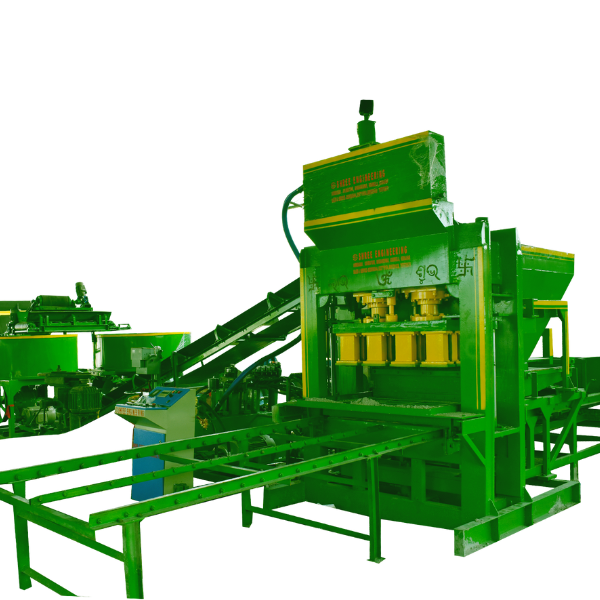

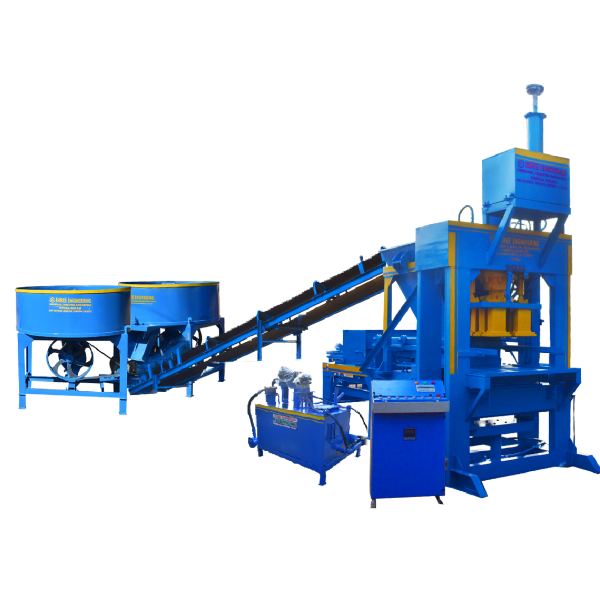

15 Bricks Automatic Fly Ash Bricks Machine

The 15 Bricks Automatic Fly Ash Bricks Machine is a highly efficient and modern solution for producing fly ash bricks. This machine integrates advanced technology to streamline the brick manufacturing process, ensuring high output and quality. Here are some key features and benefits:

High Production Capacity: Capable of producing 15 bricks per cycle, the machine enhances productivity and meets large-scale demands effectively.

Automation: The fully automated system minimizes manual intervention, ensuring consistent quality, reducing labor costs, and increasing operational efficiency.

Eco-Friendly: Utilizes fly ash, an industrial waste product, thereby promoting recycling and reducing environmental impact.

- BRICKS PER STROKE :

- TECHNOLOGY :

- Pressure :

- Model Available :

- Pan Mixer Capacity :

- Application :

- Total Power :

- 15

- Hydraulic Press

- 3000 PSI

- Normal, Belt Ejection , High Speed

- 1000-1500 KG

- Fly Ash Bricks

- 37 HP

- Per Shift production

- Operation :

- Tonnage :

- Conveyer Lenght :

- Oil Cooler :

- Warranty :

- 20000

- Automatic

- 220MT

- 20 Feet

- Yes

- 1 Year

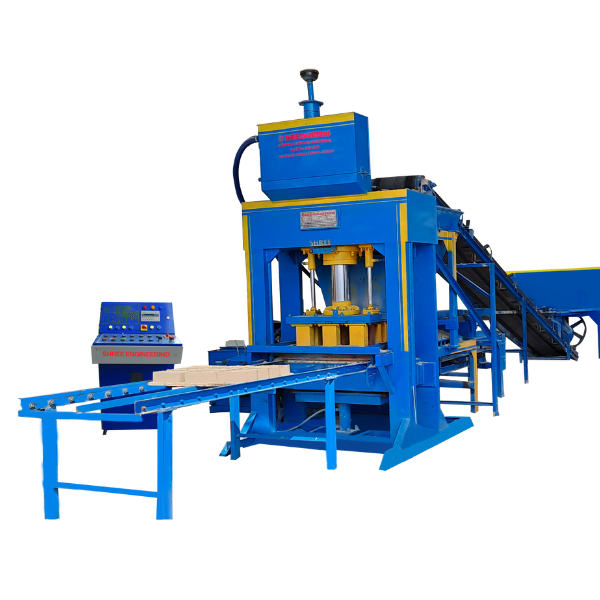

12 Bricks Automatic Fly Ash Bricks Machine

The 12 Bricks Automatic Fly Ash Bricks Machine is a state-of-the-art solution for producing high-quality fly ash bricks efficiently and effectively. Here are some key features and benefits:

Production Capacity: The machine can produce up to 12 bricks per cycle, making it ideal for medium to large-scale brick manufacturing operations.

Automation: Fully automated operations minimize manual labor, enhance precision, and ensure consistent brick quality.

Sustainable Material Usage: Utilizes fly ash, an industrial byproduct, promoting recycling and reducing environmental waste.

Robust Construction: Built with durable materials to withstand heavy-duty use, ensuring long-lasting performance and reliability.

- BRICKS PER STROKE :

- TECHNOLOGY :

- Pressure :

- Model Available :

- Pan Mixer Capacity :

- Application :

- Total Power :

- 12

- Hydraulic Press

- 3000 PSI

- Normal, Belt Ejection , High Speed

- 1000-1500 KG

- Fly Ash Bricks

- 29.5 HP

- Per Shift production

- Operation :

- Tonnage :

- Conveyer Lenght :

- Oil Cooler :

- Warranty :

- 18000

- Automatic

- 220MT

- 22 Feet

- Yes

- 1 Year

10 Bricks Automatic Fly Ash Bricks Machine

The 10 Bricks Automatic Fly Ash Bricks Machine is a sophisticated and efficient machine designed for producing fly ash bricks in medium to large quantities. Here are some key features and benefits of this machine:

Production Capacity: Capable of producing 10 bricks per cycle, this machine is well-suited for medium to high production needs, balancing efficiency and capacity.

Automation: The fully automatic system minimizes manual intervention, ensuring consistent quality and reducing labor costs.

Eco-Friendly: Utilizing fly ash, a byproduct of coal combustion, the machine promotes recycling and reduces environmental waste, contributing to sustainable building practices

- BRICKS PER STROKE :

- TECHNOLOGY :

- Pressure :

- Model Available :

- Pan Mixer Capacity :

- Application :

- Total Power :

- 10

- Hydraulic Press

- 3000 PSI

- Normal, Belt Ejection , High Speed

- 1000-1500 KG

- Fly Ash Bricks

- 29.5 HP

- Per Shift production

- Operation :

- Tonnage :

- Conveyer Lenght :

- Oil Cooler :

- Warranty :

- 15000

- Automatic

- 150MT

- 18 Feet

- Yes

- 1 Year

8 Bricks Automatic Fly Ash Bricks Machine

The 8 Bricks Automatic Fly Ash Bricks Machine is an advanced and efficient machine designed for the production of high-quality fly ash bricks. Suitable for medium to large-scale manufacturing operations, this machine offers numerous benefits and features:

High Production Capacity: Capable of producing up to 8 bricks per cycle, the machine significantly increases productivity and meets the demands of sizable construction projects.

Automation: The automated system reduces the need for manual labor, ensuring consistent quality, minimizing human error, and lowering labor costs.

Energy Efficiency: Designed to optimize energy consumption, making the machine cost-effective and environmentally friendly.

- BRICKS PER STROKE :

- TECHNOLOGY :

- Pressure :

- Model Available :

- Pan Mixer Capacity :

- Application :

- Total Power :

- 8

- Hydraulic Press

- 3000 PSI

- Normal, Belt Ejection , High Speed

- 1000-1500 KG

- Fly Ash Bricks

- 28 HP

- Per Shift production

- Operation :

- Tonnage :

- Conveyer Lenght :

- Oil Cooler :

- Warranty :

- 12000

- Automatic

- 150MT

- 18 Feet

- Yes

- 1 Year

6 BRICKS AUTOMATIC FLY ASH BRICKS MACHINE

The 4 Bricks Automatic Fly Ash Bricks Machine is a cutting-edge piece of industrial equipment designed for the efficient production of fly ash bricks. This machine is ideal for meeting medium to high-volume production needs while maintaining superior quality and consistency. Here are some key features and benefits:

High Production Capacity: Capable of producing four bricks per cycle, this machine significantly boosts productivity and can meet the demands of large construction projects.

Automation: Fully automated operations minimize manual labor, reduce errors, and ensure consistent quality in every batch of bricks produced.

Material Utilization: Uses fly ash, a byproduct of coal combustion, which promotes eco-friendly construction practices by recycling industrial waste.

Energy Efficiency: Designed to consume less power while maintaining high output, making it cost-effective and environmentally friendly.

- BRICKS PER STROKE :

- TECHNOLOGY :

- Pressure :

- Model Available :

- Pan Mixer Capacity :

- Application :

- Total Power :

- 6

- Hydraulic Press

- 3000 PSI

- Normal, Belt Ejection , High Speed

- 650 KG

- Fly Ash Bricks

- 19.5 HP

- Per Shift production

- Operation :

- Tonnage :

- Conveyer Lenght :

- Oil Cooler :

- Warranty :

- 8604

- Automatic

- 60MT

- 18 Feet

- Yes

- 1 Year

4 Bricks Automatic Fly Ash Bricks Machine

The 4 Bricks Automatic Fly Ash Bricks Machine is a cutting-edge piece of industrial equipment designed for the efficient production of fly ash bricks. This machine is ideal for meeting medium to high-volume production needs while maintaining superior quality and consistency. Here are some key features and benefits:

High Production Capacity: Capable of producing four bricks per cycle, this machine significantly boosts productivity and can meet the demands of large construction projects.

Automation: Fully automated operations minimize manual labor, reduce errors, and ensure consistent quality in every batch of bricks produced.

Material Utilization: Uses fly ash, a byproduct of coal combustion, which promotes eco-friendly construction practices by recycling industrial waste.

Energy Efficiency: Designed to consume less power while maintaining high output, making it cost-effective and environmentally friendly.

- BRICKS PER STROKE :

- TECHNOLOGY :

- Pressure :

- Model Available :

- Pan Mixer Capacity :

- Application :

- Total Power :

- 4

- Hydraulic Press

- 3000 PSI

- Normal, Belt Ejection , High Speed

- 400 KG

- Fly Ash Bricks

- 18.5 HP

- Per Shift production

- Operation :

- Tonnage :

- Conveyer Lenght :

- Oil Cooler :

- Warranty :

- 7500

- Automatic

- 50MT

- 16 Feet

- Yes

- 1 Year

4 Block Making Automatic Machine

The 4 Block Making Automatic Machine is an advanced industrial machine designed to produce high-quality concrete blocks efficiently. Suitable for medium to large-scale production, this machine offers numerous features and benefits that make it a valuable asset in the construction industry:

High Production Capacity: Capable of producing up to four blocks per cycle, significantly increasing productivity and meeting the demands of sizable construction projects.

Precision Engineering: Ensures uniform size, shape, and strength of each block, enhancing the structural integrity and aesthetic appeal of construction projects.

Durable Construction: Built with high-quality materials and components, the machine is designed to withstand rigorous use and ensure long-term reliability and durability.

Energy Efficiency: Designed to consume less power while maintaining high output, making it cost-effective and environmentally friendly.

- BRICKS PER STROKE :

- TECHNOLOGY :

- Pressure :

- Model Available :

- Pan Mixer Capacity :

- Application :

- Total Power :

- 4

- Hydraulic Press with vibration

- 3000 PSI

- Normal, High Speed

- 400 KG

- Concrete Block

- 18.5 HP

- Per Shift production

- Operation :

- Tonnage :

- Conveyer Lenght :

- Oil Cooler :

- Warranty :

- 5700

- Automatic

- 80MT

- 18 Feet

- Yes

- 1 Year

3 Bricks Automatic Rotary Fly Ash Bricks Machine

The 3 Bricks Automatic Rotary Fly Ash Bricks Machine is a specialized industrial machine designed for the efficient production of fly ash bricks. Here are some key features and benefits:

Rotary Operation: The rotary mechanism ensures continuous and smooth production, enhancing the efficiency of the brick-making process.

High Precision: Capable of producing three bricks per cycle, this machine ensures consistent quality and uniformity in brick size and shape.

Automation: Fully automated operations minimize manual labor, reduce errors, and ensure high-quality output.

Material Utilization: Utilizes fly ash, a byproduct of coal combustion, promoting eco-friendly construction practices by recycling industrial waste.

- BRICKS PER STROKE :

- TECHNOLOGY :

- Pressure :

- Model Available :

- Pan Mixer Capacity :

- Application :

- Total Power :

- 3

- Hydraulic Press

- 3000 PSI

- Normal, Belt Ejection , High Speed

- 1000-1500 KG

- Fly Ash Bricks

- 28 HP

- Per Shift production

- Operation :

- Tonnage :

- Conveyer Lenght :

- Oil Cooler :

- Warranty :

- 10000

- Automatic

- 90MT

- 20 Feet

- Yes

- 1 Year